From Sample to Solution – Simple & Fast

Tribo-Simulator

Why do you need a Tribo-simulator?

You wish to know

the wear rate of metallic materials and hard coatings,

the coefficient of Friction (CoF) of metallic materials and hard coatings,

the thickness of hard coatings,

the layer thickness of a multilayer thin film,

the adhesion strength of a hard coating,

the Dynamic Coefficient of Friction (CoF),

track surface roughness, tribofilm formation, or coating integrity.

If you wish to address mechanical failures in metallic materials and hard coatings, the tribo-simulator can help you find a solution.

The Tribo-Simulator DCK-01 is designed to provide quantitative and reproducible tribological data by precisely controlling and monitoring the key operating parameters that govern material thickness degradation, wear behaviour, and frictional response. The system integrates high-resolution force sensors, displacement measurement modules, and digital data acquisition to track surface interactions during sliding contact accurately.

Thickness Loss Measurement

The progressive reduction in coating thickness is monitored by tracking the vertical displacement of the specimen holder during testing. As material is removed due to sliding contact, the system records micron-level changes in sample height, enabling direct determination of thickness loss.

Thickness degradation depends on:

Applied normal load, Sliding speed and duration, Material hardness and adhesion strength, Coating bonding quality and density, Lubrication conditions

Wear Measurement

The DCK-01 determines wear using dimensional-loss measurements combined with sliding-distance data. Wear is quantified through linear wear-depth measurement, wear-track width and depth analysis, and volume-loss calculations.

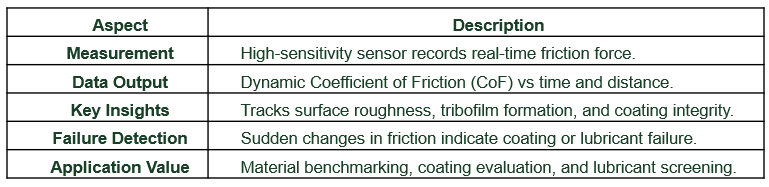

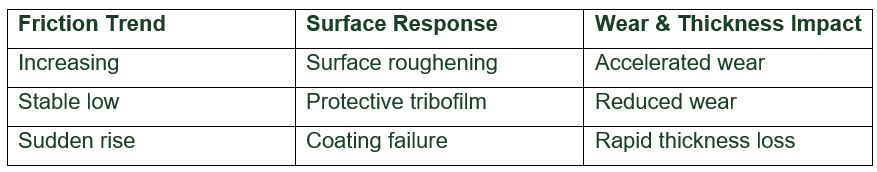

Friction Measurement

Correlation

Send us your sample → We perform precision testing → You receive actionable results